Client: Cherokee County Water & Sewage Authority in Woodstock, Georgia

Opportunity: Eliminate persistent odors and prevent corrosion caused by high levels of hydrogen sulfide in the Rose Creek WWTP headworks building.

The Challenge

Just a few hundred yards from a neighborhood and a golf course, Rose Creek Wastewater Treatment Facility struggled with a persistent problem: odors from the headworks building were regularly drifting into the surrounding community, leading to repeated complaints and growing concern. Hydrogen sulfide (H₂S) levels inside the building were spiking above 25 ppm during pump cycles, leading to serious corrosion of equipment, electronics, and even structural components such as roof supports.

“Replacing ion tubes annually significantly reduces the maintenance effort and cost, compared to traditional exhaust air scrubbers.”

— Anthony McFarland, Plant Operations Manager, Rose Creek

Meanwhile, employees were reluctant to enter the building due to the stench and associated health risks. The existing odor control system, which relied on chemical scrubbers and large storage tanks of sodium hydroxide and bleach, was hazardous, costly to maintain, and space-intensive.

With exhaust fans and heaters running 24/7 and barely improving the air quality, it was clear the current system could no longer meet the facility’s operational or safety goals to:

- Neutralize odors exhausted from the building

- Reduce corrosion caused by H₂S

- Lower chemical and maintenance costs

- Create a healthy, safe work environment

- Reduce energy consumption

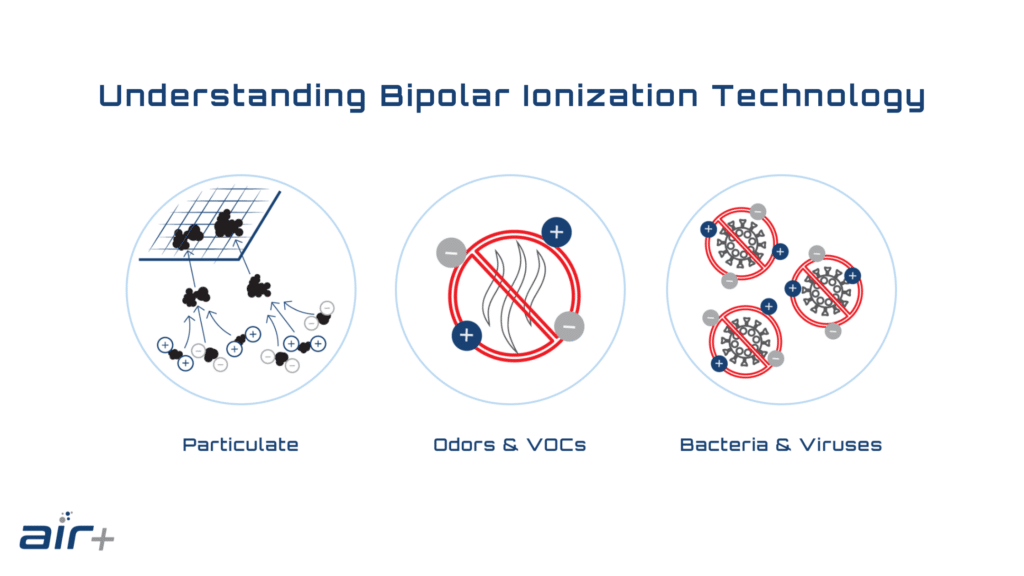

When evaluating alternatives, carbon filtration was ruled out due to the high concentration of H₂S, and chemical scrubbers were deemed unsustainable due to maintenance burdens and high costs. The facility looked to a new, more holistic solution: ionization from Air+.

Approach

Rose Creek identified Air+ ionization technology as capable of tackling both odor and corrosion simultaneously—a feat unattainable by legacy odor control solutions. The system was installed as part of a broader building improvement project aimed at addressing odor and corrosion.

By breaking down H₂S inside the facility rather than just treating exhaust air, the system addresses odor and corrosion at the source and requires a much smaller footprint than the old chemical scrubber and associated tanks.

“Ionization was the only technology that checked all the boxes—odor control, corrosion prevention, and cost-efficiency.”

— George Parks, Wastewater Facilities Assistant Manager, Cherokee County Water & Sewage Authority

The Impact

Since installing the Air+ system in 2017, hydrogen sulfide levels inside the building have dropped nearly 100%, continuing to remain close to 0.0 ppm, according to onsite gas monitors. For the first time, the plant achieved consistent odor elimination without chemical scrubbers, ongoing chemical purchases, or employee complaints.

There have been no signs of increased corrosion on infrastructure, electronics, or mechanical systems that were once at risk of premature failure. Employees report that the building is now a pleasant place to work, and the maintenance staff no longer resist entering the space.

Importantly, the facility has also eliminated community odor complaints, improving public trust and avoiding regulatory scrutiny.

The system continues to operate with minimal maintenance, requiring only annual ion tube replacement, delivering ongoing cost savings and extending the life of building components that were once at risk of early failure.

“It’s been eight years and we haven’t had a single odor complaint. More importantly, our infrastructure is safe from corrosion. Air+ delivered what we needed, and then some.”

— Jamie Veley, Wastewater Facilities Assistant Manager, Cherokee County Water & Sewage Authority