Innovative Odor Control Technology For The Wastewater Industry

Traditional odor control methods such as the use of chemical based wet scrubbers or carbon adsorption systems are both capital and maintenance intensive. The Air+ approach provides unique technology for odor control with much lower total cost of ownership.

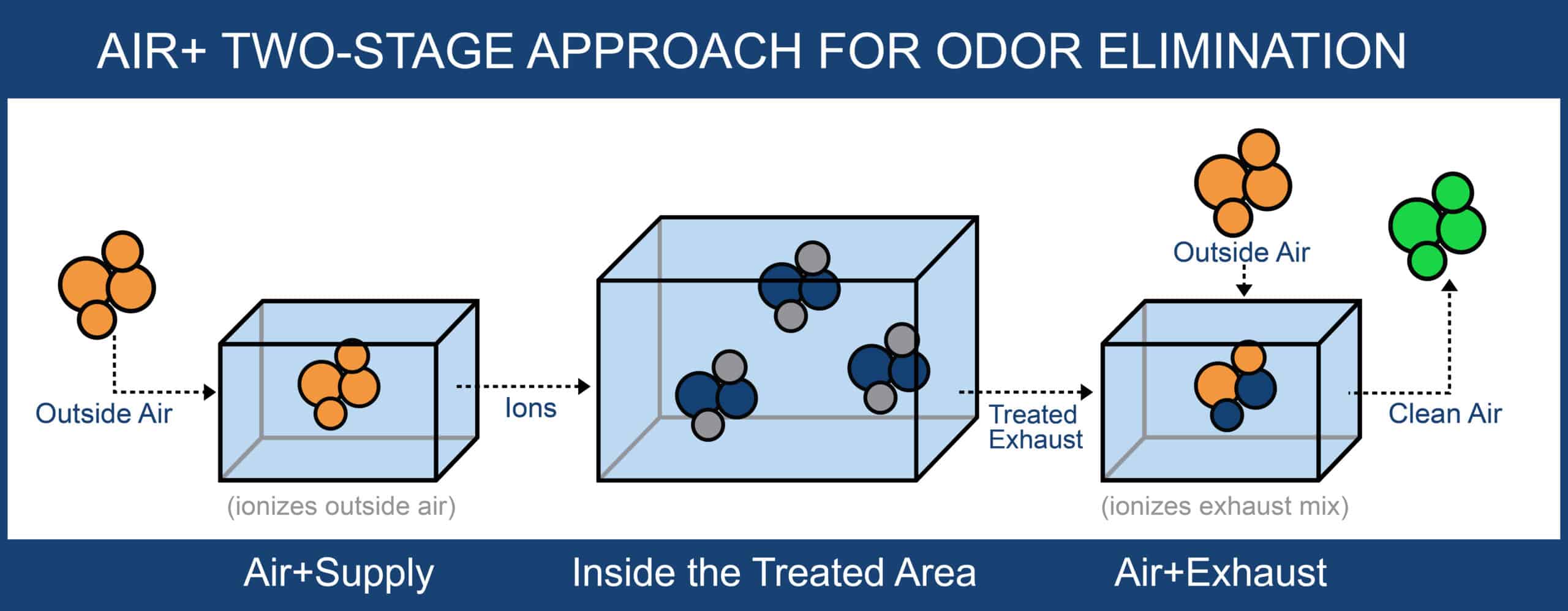

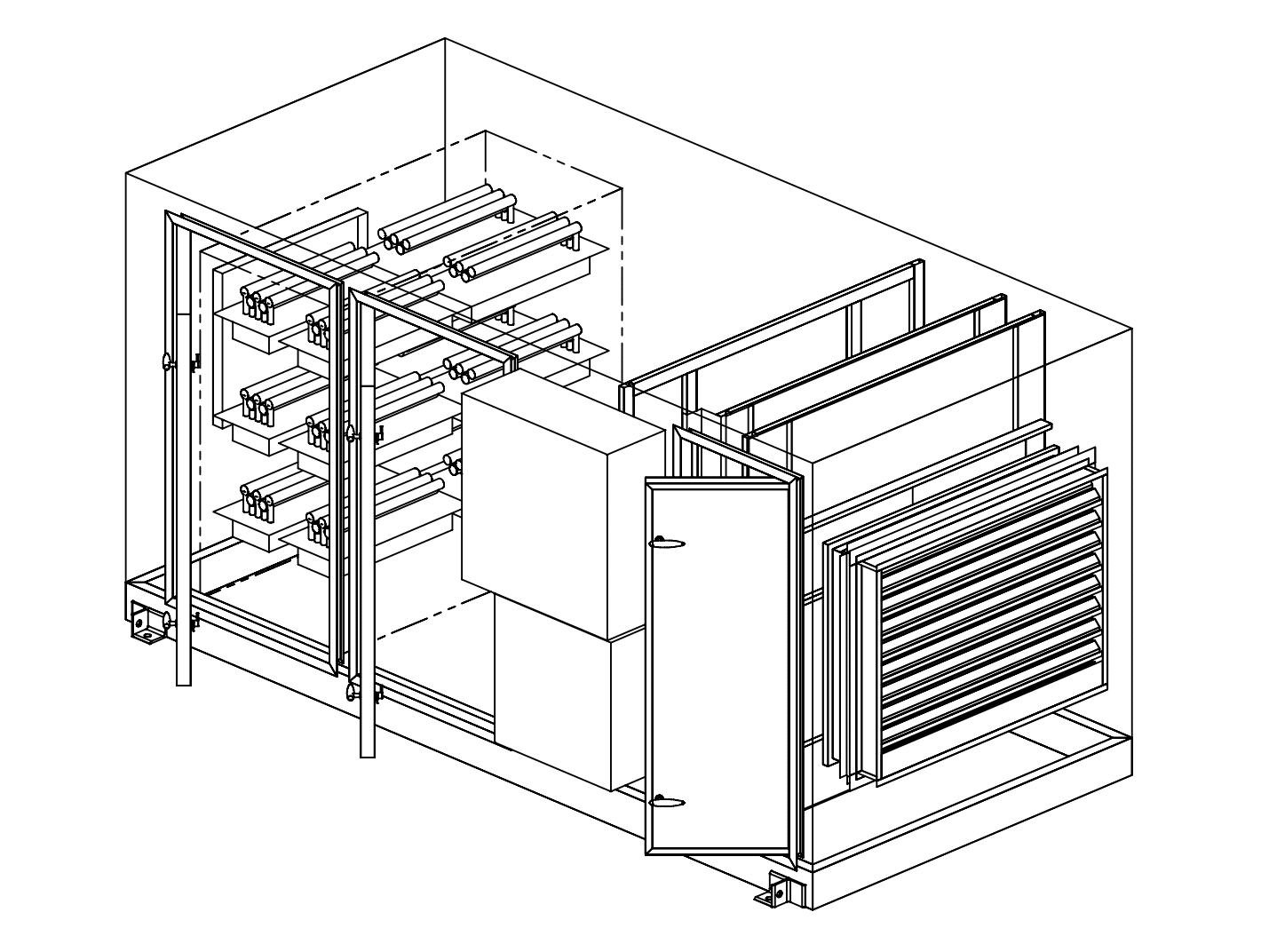

Unlike legacy odor control systems that utilize carbon, chemicals or biological media to scrub air exhausted out of a building or headspace, Air+ ionization systems supply highly ionized air to the application areas. These ions proactively attack the contaminants at the source, while vastly improving indoor working conditions. These ions, along with system airflow, deliver positively and negatively charged oxygen ions to where they are needed most. A specific quantity of ionizers, based on system airflow requirements, are housed in an industrial supply air handler. In some cases an exhaust scrubber is required as well.

Effective ionization system configuration requires an engineered ventilation design. Proper ductwork material selection, sizing, location, along with ionized air and facility exhaust locations, are critical for system performance. Air+’s AirDuct properly distributes ions throughout application areas to achieve superior results for wastewater related applications. Air+ ionization systems are factory engineered to address a wide range of airflow rates and contaminant concentrations. Application areas include:

- Headworks Buildings

- Dewatering Rooms

- Truck Loading Facilities

- Process Tank Headspaces

- Large Pump/Lift Stations and Wet Wells

Air+ Odor Control Technology Delivers:

- Cost Effective Odor Removal – Removes odors with a relatively small footprint that requires no storage tanks and incorporates optional heating systems.

- Corrosion Control – By proactively attacking H2S and other corrosive gases inside the application area, the corrosion of metal components is significantly reduced or eliminated.

- Reduced Maintenance – With no moving parts other than fans, Air+ systems require minimal maintenance, costing typically 60-70% less than competing exhaust-only systems. Chemical pump maintenance, reordering of chemicals, and replacement of carbon media are not required.

- Low Energy Consumption – One Air+ ionization unit effectively treats 500 to 1000 CFM, but only requires 50 watts of power. Since ionization systems utilize the facility volume as a reaction chamber instead of using a tank as with exhaust-only scrubbers, pressure drop is low and the resulting fan power requirement is 75-80% less than traditional solutions.

- No Chemicals Required – Air+ ionization technology generates positive and negative ions with highly oxidative capacity that break down a wide variety of wastewater-related, odorous compounds without the use of costly and hazardous chemicals.

- Retrofit into Existing Facilities – Air+ systems can be retrofit into existing HVAC air handlers, resulting in significant capital cost and installation savings. For those facilities without HVAC systems, Air+ equipment requires a relatively small footprint.

A Small Solution For A Big Problem

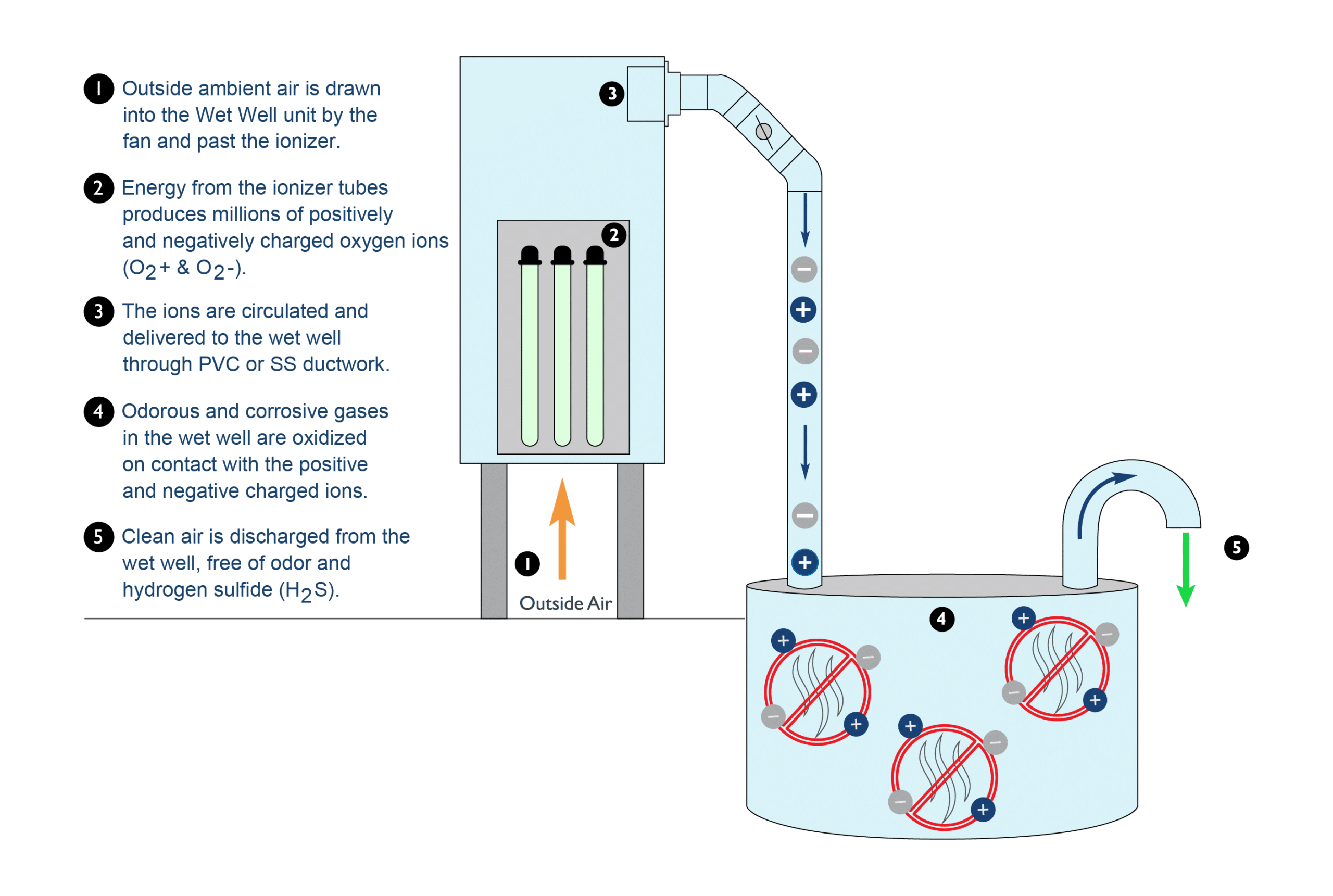

Foul-smelling odors from pump stations, wet wells, manholes, interceptors and holding tanks can interrupt and deteriorate everyday life. Using Air+ bipolar ionization technology, the Air+ Odor Beast eliminates and controls odors that impact the lives of those living and working nearby. The unit is designed to treat the head space in a tank, making it an ideal solution for

- Wet Wells

- Clarification Systems

- Holding Tanks

- Solids Processing

- Pump Stations

- Equalization Tanks

- Septic Tanks

- Biological Systems

- Septage Receiving Stations